+86 13600513715

+86 13600513715

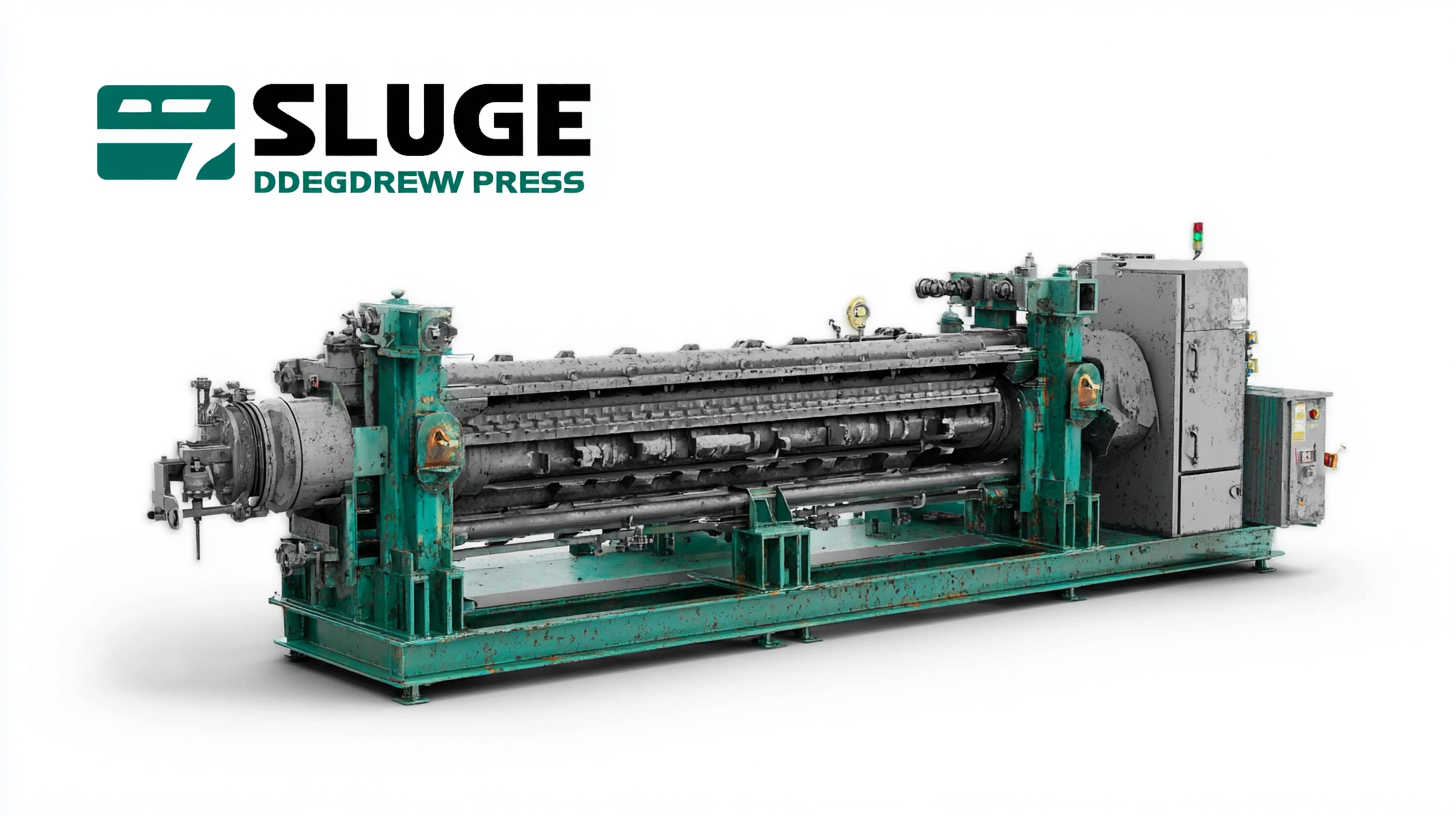

As industries increasingly turn to innovative technologies to address environmental challenges, the significance of efficient sludge management cannot be overstated. The advent of the Sludge Dewatering Screw Press has revolutionized wastewater treatment processes, as highlighted by a 2022 report from the Global Environment Facility, which noted that conventional dewatering methods often leave up to 30% of solids in the output. In contrast, the Sludge Dewatering Screw Press technology can reduce this to as low as 10%, significantly enhancing operational efficiency and sustainability. However, industries face various challenges in implementing this cutting-edge technology, including high initial investment costs, ongoing maintenance requirements, and the need for specialized training to operate these sophisticated systems effectively. As businesses strive to meet stricter environmental regulations and improve their resource recovery processes, understanding these challenges is crucial for successful adoption of the best practices in sludge dewatering technologies.

When selecting a reliable sludge dewatering screw press supplier, industries must consider several key qualities that can significantly impact operational efficiency and cost-effectiveness. According to a report by the Global Water Intelligence, the demand for advanced sludge management solutions has increased by over 23% in recent years, emphasizing the importance of partnering with a dependable supplier. One essential quality to look for is the supplier's experience and expertise in the industry. Suppliers who have a proven track record in providing dewatering solutions are more likely to deliver products that meet stringent performance standards, which can lead to a reduction in operational costs by up to 15%.

Another critical factor is the availability of customer support and after-sales service. A comprehensive support system ensures that any operational issues are addressed promptly, minimizing downtime. A recent study from the Environmental Protection Agency indicated that inadequate support from suppliers could lead to an average of 10% to 20% increase in maintenance costs for dewatering equipment. Thus, industries should prioritize suppliers who offer robust technical assistance and regularly scheduled maintenance services. Overall, choosing a supplier with these qualities can facilitate smoother operations and enhance long-term sustainability.

Implementing sludge dewatering technology, particularly through the use of screw press systems, presents a number of challenges for various industries. One of the primary issues is the initial capital investment required for purchasing and installing such advanced equipment. Many companies, especially smaller players, struggle to allocate sufficient funds for high-quality dewatering systems, which can hinder their ability to effectively manage waste and comply with environmental regulations.

Additionally, operational challenges can arise in the form of maintenance and management of the dewatering process. Industries often face difficulties in ensuring consistent performance and efficiency of the screw press systems, which can lead to variations in sludge quality and increased operational costs. Staff training also plays a crucial role, as employees must be adept at handling the technology to optimize results. Inadequate training may result in operational inefficiencies and increased downtime, further complicating the implementation of sludge dewatering solutions.

When industries consider upgrading their wastewater treatment processes, selecting the right sludge dewatering technology provider is crucial. Evaluating potential partners requires a comprehensive understanding of their capabilities and the specific needs of your operation. One effective approach is to assess the supplier's experience and expertise in implementing screw press technology. Look for providers with a proven track record in various industrial applications, as this can significantly impact the performance and reliability of the equipment.

Tips: Always inquire about case studies or client testimonials to gauge the effectiveness of their technology in real-world scenarios. Understanding how their systems have performed under different conditions can provide valuable insights into their reliability and efficiency.

Another important factor is the level of technical support offered by the provider. A responsive and knowledgeable support team can make a significant difference when troubleshooting issues or optimizing performance. Ensure that the provider offers training, maintenance services, and timely communication to address any potential challenges during operation.

Tips: Ask about their training programs and ongoing support initiatives to ensure your team is well-equipped to operate and maintain the equipment effectively.

| Challenge | Impact on Operations | Evaluation Criteria | Recommended Approach |

|---|---|---|---|

| High Energy Consumption | Increased operational costs and environmental footprint. | Energy efficiency ratings and machine specifications. | Select providers offering energy-efficient technologies. |

| Sludge Characteristics Variability | Impacts dewatering performance and consistency of output quality. | Capability to handle different sludge types. | Conduct pilot tests with providers using different sludge samples. |

| Maintenance Requirements | Downtime and additional costs for repairs and maintenance. | Maintenance frequency and ease of access for servicing. | Choose models with user-friendly designs and low maintenance needs. |

| Capital Investment | Budget constraints and justifying ROI to stakeholders. | Total cost of ownership and payback period analysis. | Evaluate total lifecycle costs over initial purchase price. |

| Regulatory Compliance | Risk of penalties and forced adjustments in operations. | Certification and compliance history of the technology. | Select technologies with a proven compliance track record. |

When it comes to selecting dewatering equipment, industries must navigate a myriad of choices, especially when considering the best sludge dewatering screw press technology. One of the essential questions to ask potential suppliers is about the equipment's efficiency and capacity. For instance, according to the Water Environment Federation, advanced dewatering technologies can achieve solid-liquid separation efficiencies exceeding 90%, which is crucial for industries looking to reduce disposal costs and environmental impact. Understanding a supplier's track record in meeting these efficiency benchmarks will help companies make informed decisions.

Another critical aspect to inquire about is the maintenance requirements and durability of the equipment. A report from the American Society of Civil Engineers indicated that the lifecycle cost of dewatering equipment can significantly impact long-term operational expenses. Buyers should seek suppliers who provide transparent maintenance schedules and durability metrics, ensuring they invest in equipment that not only performs well initially but also stands up to the rigors of continuous operation. By asking these questions, companies can align themselves with suppliers who understand the industry's demands for reliability and performance.

In the quest for enhanced sludge dewatering efficiency, industries face several challenges while adopting the best sludge dewatering screw press technology. One key issue is the variability in sludge characteristics, which can lead to fluctuating performance levels. According to a study by the Water Environment Federation, plants utilizing screw press systems often report a 15% to 20% increase in solid recovery when maintaining optimal operational parameters. To improve efficiency, it is essential to conduct regular sludge characterizations and adjust dewatering techniques accordingly.

In the quest for enhanced sludge dewatering efficiency, industries face several challenges while adopting the best sludge dewatering screw press technology. One key issue is the variability in sludge characteristics, which can lead to fluctuating performance levels. According to a study by the Water Environment Federation, plants utilizing screw press systems often report a 15% to 20% increase in solid recovery when maintaining optimal operational parameters. To improve efficiency, it is essential to conduct regular sludge characterizations and adjust dewatering techniques accordingly.

Tip: Implement routine monitoring of the sludge composition to identify changes that may impact dewatering performance.

Another common challenge is the maintenance of the equipment, which, if neglected, can lead to decreased efficiency and higher operational costs. Data from the American Society of Civil Engineers indicates that proactive maintenance schedules can reduce downtime by up to 30%. Keeping the equipment clean and regularly inspecting key components can prevent unexpected failures.

Tip: Establish a preventive maintenance program that includes thorough cleaning and inspection intervals to maximize equipment uptime.

Tracking performance metrics post-dewatering can also reveal critical insights into areas of improvement. Continuous monitoring allows operators to fine-tune their processes, ensuring they achieve the best sludge dewatering outcomes over time while maximizing resource efficiency.