+86 13600513715

+86 13600513715

In today's water treatment industry, efficiency is crucial. The "Rotating Drum Filter" has emerged as a popular solution. Experts like Dr. Emily Carter, a leading figure in water filtration, once stated, "The Rotating Drum Filter can significantly improve water clarity while reducing operational costs." This technology offers reliable filtration through a rotating mechanism that continuously screens out solids.

While the advantages are clear, it's essential to consider some limitations. For example, some systems may require regular maintenance to ensure optimal performance. Not all Rotating Drum Filters are designed equally. Factors such as design and material can affect their longevity. Users should carefully evaluate their specific needs.

Moreover, the initial investment in these systems might deter some. However, the long-term savings on operational expenses often justify the cost. As we explore the best options, understanding the balance between efficiency and upkeep proves vital. The future of water treatment could hinge on optimizing these filters for greater sustainability.

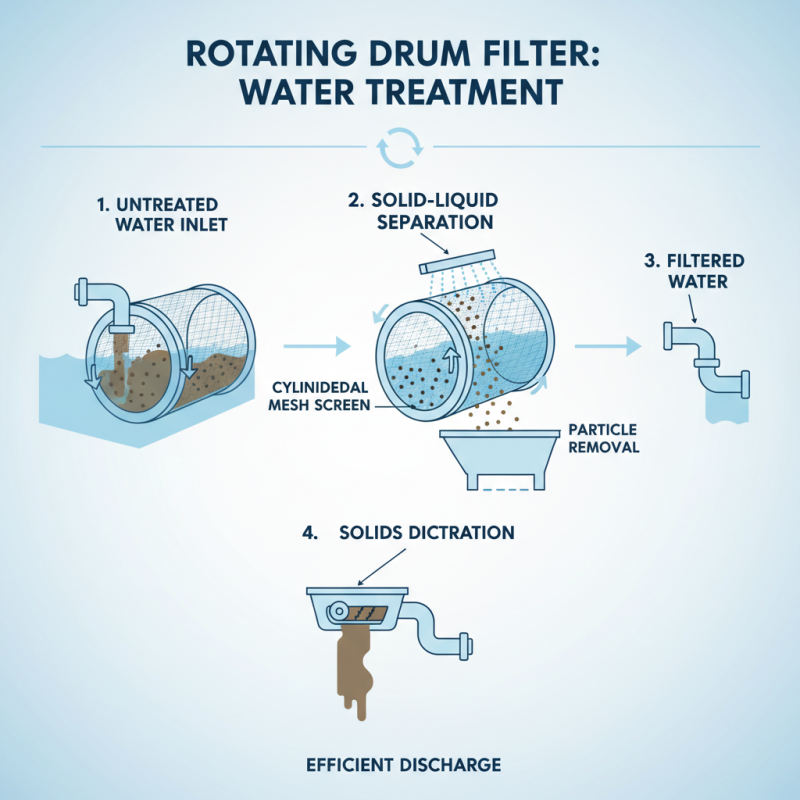

Rotating drum filters are essential in modern water treatment. They utilize a cylindrical mesh screen to separate solids from liquids. Water flows over the drum, and solids get trapped on the screen. This process allows for efficient removal of particles.

The effectiveness of a rotating drum filter depends on its design and maintenance. A well-constructed drum can handle varying water qualities. However, sometimes the mesh can get clogged. Regular cleaning is necessary to ensure optimal performance. Operators must pay attention to the filtration rate.

These filters are versatile, suitable for different applications. They can be used in industrial settings or recreational water facilities. Some facilities may find that the setup requires adjustments. This forces operators to evaluate their system continually. Over time, the challenge is to balance efficiency and longevity. A rotating drum filter is a smart choice, but it also demands careful oversight.

When choosing a rotating drum filter for water treatment, several key features come into play. The filtration mesh size is crucial. A smaller mesh size captures finer particles. However, this can lead to clogging. Regular maintenance is essential. Users must balance efficiency with ease of cleaning.

The flow rate is another important aspect. Higher flow rates mean more water processed in less time. But if the flow is too fast, it may not filter effectively. Users should consider their specific needs. Adjustability can be beneficial. This allows for customizing filtration based on water quality.

Lastly, energy consumption matters. Efficient filters save energy and reduce costs. Yet, some may neglect this aspect in the decision-making process. A thorough assessment is necessary. Understanding energy use can impact long-term expenses and sustainability goals. Always reflect on the overall efficiency and cost-effectiveness.

Rotating drum filters are gaining popularity for their efficiency in water treatment. These filters use a cylindrical design to trap debris effectively. Water flows into the drum, and as it turns, solids are collected on the surface. This process allows for continuous operation, reducing downtime. For facilities, this means less manpower and lower maintenance costs.

The benefits of rotating drum filters go beyond mere efficiency. They significantly reduce the amount of waste generated. As they capture solids, fewer contaminants enter the water system. This leads to cleaner water for various uses, including irrigation and industrial processes. Implementation is relatively straightforward, yet the initial adjustment can be tricky.

One key aspect to consider is the potential for clogging. Regular monitoring is essential to ensure optimal performance. Users may need to adapt their techniques based on the type of solids present. Some find it challenging to maintain a consistent flow rate. However, the advantages often outweigh these challenges. Embracing the learning curve can lead to profound improvements in water quality.

| Feature | Description | Benefits |

|---|---|---|

| High Efficiency | Removes solids and debris effectively from water. | Enhances water clarity and quality. |

| Low Maintenance | Requires less frequent cleaning and service. | Reduces operational costs over time. |

| Automatic Functioning | Operates with minimal manual intervention. | Increases convenience and reliability. |

| Compact Design | Space-saving and easy to install. | Ideal for facilities with limited space. |

| Versatile Applications | Suitable for various industries including aquaculture, wastewater treatment, and more. | Allows for multi-functional use and adaptability. |

Rotating drum filters are essential in water treatment applications, providing efficient solid-liquid separation. They are versatile and used in various industries, including aquaculture, wastewater treatment, and food processing. Research indicates that rotating drum filters can achieve up to 90% removal efficiency of suspended solids. This efficiency is crucial for meeting regulatory standards.

There are several types of rotating drum filters. The first type uses a fine mesh screen. It captures smaller particles effectively. Another type employs different filtration media, which can enhance treatment capabilities. Systems with backwashing features help maintain performance. Studies show that these systems can reduce maintenance downtime significantly. However, operators often face challenges in selecting the right filter for their specific needs. Misjudging the required filtration level can lead to ineffective treatment.

Performance analysis can show these filters are not foolproof. Some users report clogging issues despite high efficiency claims. This inconsistency can complicate operations and increase costs. It is essential to monitor filter performance continuously. Regular maintenance and proper user training can mitigate potential drawbacks and improve the overall treatment process. This focus on optimization is critical for efficient water management.

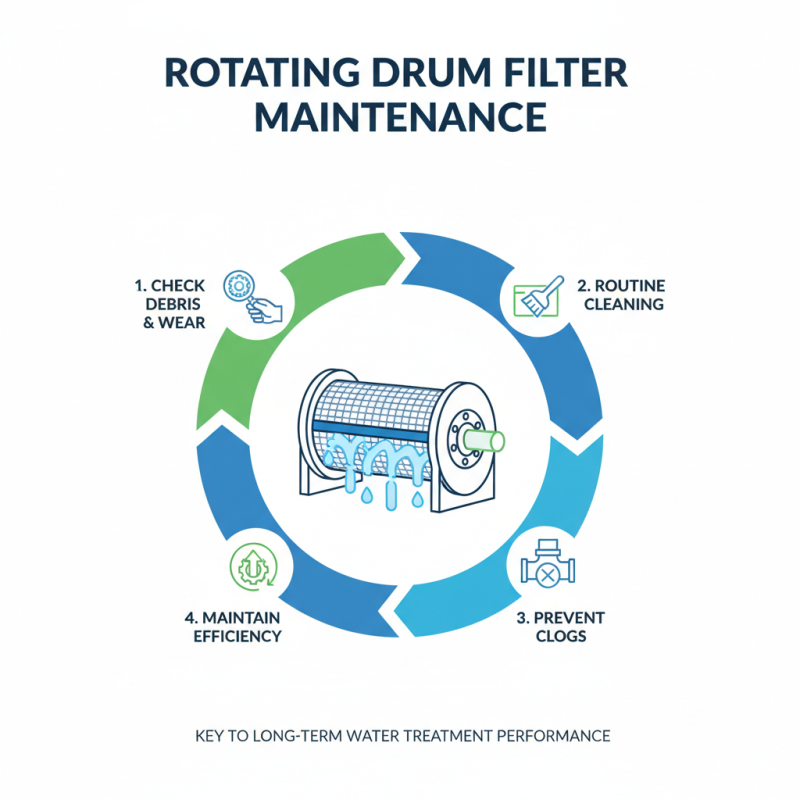

Rotating drum filters are vital in water treatment processes. Proper maintenance is crucial for their long-term efficiency. Regularly check for debris buildup. Signs of wear can indicate larger issues. Cleaning the filter surface should be routine. Neglect can lead to clogs. A clogged filter decreases performance significantly.

Inspect the motor and drive system frequently. Listen for unusual sounds. They can signal mechanical problems. Ensure that the filter's rotation speed is within the recommended range. Poor alignment can cause vibrations. This may affect overall functionality. Keep a log of maintenance activities. Documenting your efforts helps identify recurring problems. Monitoring performance metrics is essential for identifying when something feels off.

Adjusting operating parameters might be necessary. This ensures optimal performance. Balancing flow rates can be tricky. Experimentation can lead to better efficiency. Moreover, any maintenance performed should be done carefully. Rushed work often leads to mistakes, impacting filter longevity. Regular training on maintenance protocols can enhance the team's effectiveness. Always be ready to learn and adjust.