+86 13600513715

+86 13600513715

Efficient waste management remains a critical challenge in today's world. As the industry evolves, innovations emerge, particularly in Screw Press Dewatering techniques. Renowned expert Dr. Emily Chen once remarked, "The future of waste management hinges on effective dewatering solutions." This statement highlights the importance of adopting modern methods to enhance efficiency.

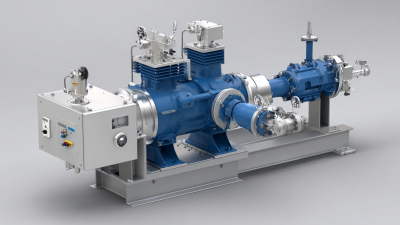

Screw Press Dewatering stands out because of its reliability and effectiveness. This technique utilizes a screw mechanism to separate solids from liquids. It's particularly useful in industries that deal with slurry, such as food processing and wastewater management. Even with its advantages, many facilities struggle to implement it fully. Some may overlook maintenance, leading to inefficiencies and increased costs.

Understanding the nuances of Screw Press Dewatering can lead to significant improvements. Every facility has different needs. Therefore, it is essential to assess individual requirements carefully. The right technique can minimize waste and maximize resources, but executing it perfectly is no easy feat. It requires constant evaluation and adaptation to ensure optimal performance.

Screw press dewatering technology has gained prominence in waste management due to its efficiency. This method uses a mechanical screw system to separate water from solid waste. According to a report by the Environmental Protection Agency, effective dewatering can reduce waste volume by up to 90%. This efficiency makes it an attractive option for various industries, including agriculture and food processing.

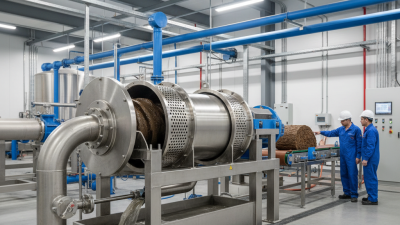

Dewatering not only promotes sustainability but also reduces waste disposal costs. The technology operates at lower energy levels compared to traditional methods. A recent study shows that screw presses can achieve a dry solids content of over 30%, making them highly effective for handling sludge. However, there are challenges. Maintenance can be demanding, leading to downtime. Operators must be trained properly to handle these machines effectively.

Tip: Regular maintenance checks can address wear and tear before they cause major issues. Consider investing in training for your team. It can enhance operational efficiency significantly. Implementing screw press technology requires a holistic approach to waste management. It’s not just about the machinery; processes need thoughtful evaluation.

Screw press dewatering techniques are gaining traction in waste management. They offer significant advantages. One primary benefit is increased efficiency. By removing excess water, waste volume reduces markedly. This makes transportation easier and more cost-effective. Facilities can manage waste better, leading to improved operational performance.

Effective screw presses also minimize energy consumption. These systems often utilize less power compared to traditional methods. This reduction can lead to lower operational costs. Operators may find they can further cut expenses with maintenance of these machines. Proper maintenance is crucial. Neglecting regular checks can lead to inefficiencies.

When implementing screw press technology, keep these tips in mind. Regularly inspect the press for wear and tear. Such attention prevents breakdowns. It’s essential to train staff on optimal operation techniques. An informed team enhances efficiency. Remember, not all waste types dewater the same. Some may require adjustments or different approaches. Reflecting on these aspects can optimize your dewatering process.

This chart presents key performance metrics for screw press dewatering techniques in waste management. The data reflects sludge volume reduction, water recovery efficiency, energy consumption, and maintenance frequency, highlighting the effectiveness and efficiency of screw press technology in optimizing waste management processes.

The screw press operates through a simple, yet effective mechanism. As waste enters the system, a rotating screw draws it into a chamber. This chamber narrows, exerting high pressure on the material. Water is squeezed out, separating liquid from solids. The design of the screw press ensures continuous operation with minimal energy use. However, achieving optimal performance requires careful calibration.

While these machines can be efficient, challenges remain. The sludge composition can vary significantly, which impacts dewatering effectiveness. Operators must monitor conditions closely. Some materials might clog the system, leading to downtime. Regular maintenance is essential to prevent wear and tear, affecting reliability.

Dewatering is not without its complexities. The balance between speed and efficiency often leads to trade-offs. An operator might need to adjust the feed rate based on real-time feedback. Exploring various pressure settings can enhance performance. However, this requires skill and experience, which may be lacking in some facilities. Each adjustment opens up new questions about the process.

| Technique | Operating Principle | Efficiency (%) | Typical Applications | Maintenance Frequency |

|---|---|---|---|---|

| Single-Screw Press | Utilizes a rotating screw to compress sludge, enhancing water removal. | 85% | Municipal wastewater treatment | Monthly |

| Twin-Screw Press | Employs two intermeshing screws for increased shear and compaction. | 90% | Industrial sludge processing | Biweekly |

| Vertical Screw Press | Vertical design facilitates gravity drainage and higher hydraulic pressure. | 88% | Food processing industry | Quarterly |

| Horizontal Screw Press | Horizontal orientation ensures uniform feed and pressure application. | 84% | Agricultural waste treatment | Monthly |

| Screw Press with Flocculation | Integrates flocculation to agglomerate solids before pressing. | 92% | Sludge and mixed waste treatment | Weekly |

The screw press is gaining popularity in waste management, especially for dewatering sludges and organic materials. Compared to traditional methods like centrifuges and filter presses, it offers significant advantages. A recent report from the American Society of Civil Engineers highlighted that screw presses have a lower energy requirement, reducing operating costs by up to 30%. This efficiency makes them attractive for municipalities and industrial facilities alike.

Centrifuge dewatering can be effective, but it often demands higher energy and maintenance. Filter presses, while reliable, require extensive manual labor and can have higher downtime due to the need for frequent cleaning. Screw presses, on the other hand, are known for their continuous operation and less frequent maintenance needs. They handle varying feed characteristics better. However, they may not achieve the dryness levels of centrifuges in specific scenarios.

Tip: Regular maintenance can enhance the performance of screw presses. Monitor wear parts closely to avoid unexpected downtime. Another tip is to consider material characteristics before choosing a dewatering method. This ensures that your choice aligns with the specific waste type you are processing.

Screw press dewatering techniques are evolving. These methods promise better efficiency in waste management. As sustainability becomes crucial, innovations in this field are gaining traction. Future trends indicate a shift toward energy-efficient designs. Many companies are exploring this technology. However, some systems still fall short of expectations.

Tips for implementing screw press dewatering: Start with a thorough needs assessment. Understand your waste characteristics. A tailored approach leads to better outcomes. Regular maintenance is important too. Neglecting this can lead to inefficiencies.

Furthermore, integrating smart technology can optimize performance. Real-time monitoring can identify issues early. However, relying too much on technology can be risky. Human judgment is essential. Balancing technology use with human oversight is vital for success. The future looks promising, but challenges remain.